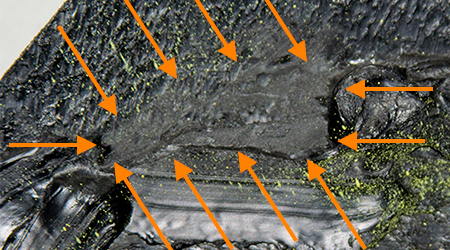

Just 4 square feet can cost you.

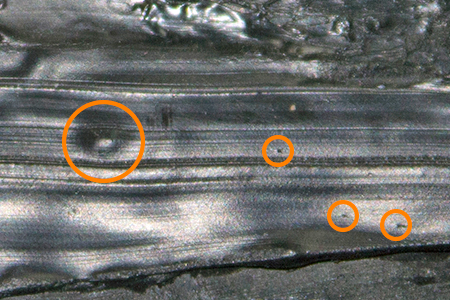

This is a photograph of an actual extrusion weld salvaged from a construction site. We noted 14 different problems, each of which could lead to containment failure, in an area that is less than 2 feet x 2 feet.

Imagine the potential liability (and repair costs) if this caused a major containment failure on your project.

(Mouse over the pins to see a detailed description.)

Heat Damage From Tacking Process

CAUSE: Usually caused by carelessness.EFFECT: Creates an additional repair, or weak point if not repaired.

CAUSE: Usually caused by carelessness.EFFECT: Creates an additional repair, or weak point if not repaired.Weld Is Too Thin

CAUSE: Inexperience or improper welding technique.EFFECT: Low tensile strength at weld.

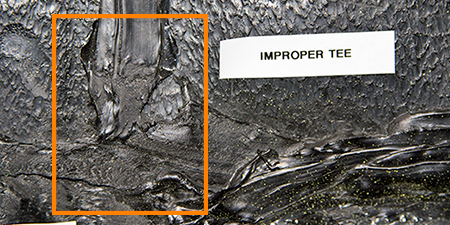

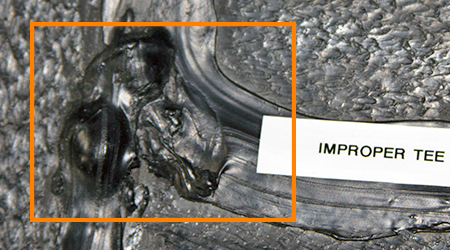

CAUSE: Inexperience or improper welding technique.EFFECT: Low tensile strength at weld.Improper Tee

CAUSE: Inexperience or improper welding technique. EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.

CAUSE: Inexperience or improper welding technique. EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.Fishmouth

CAUSE: Uneven matching between top and bottom material overlap at seam joint.EFFECT: Usually a sharp, unyielding ridge in the material that is stressed and can fail over time.

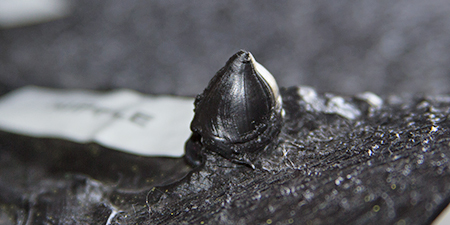

CAUSE: Uneven matching between top and bottom material overlap at seam joint.EFFECT: Usually a sharp, unyielding ridge in the material that is stressed and can fail over time. Nipple

CAUSE: Inexperience, improper welding technique, or carelessness.EFFECT: Crystallization and burn-thru. Also will damage overlying geosynthetics.

CAUSE: Inexperience, improper welding technique, or carelessness.EFFECT: Crystallization and burn-thru. Also will damage overlying geosynthetics.Lack of Extrudate

CAUSE: Operator missed the overlap area during welding.EFFECT: No seam = Leak.

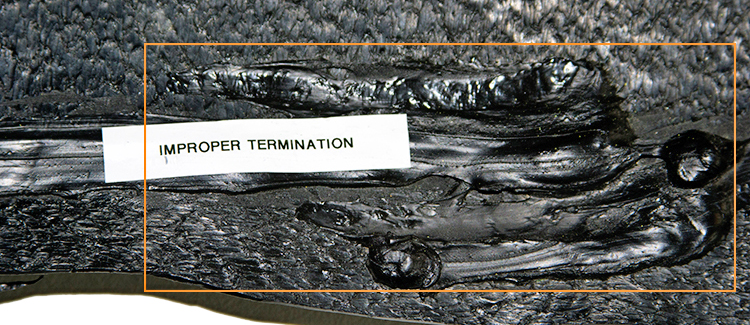

CAUSE: Operator missed the overlap area during welding.EFFECT: No seam = Leak.Improper Termination

CAUSE: Inexperience or improper welding technique.EFFECT: Adhesion failure if not abraded. Leaks if not aligned. Burn-thru and crystallization from multiple heating events.

CAUSE: Inexperience or improper welding technique.EFFECT: Adhesion failure if not abraded. Leaks if not aligned. Burn-thru and crystallization from multiple heating events.Lack of Penetration

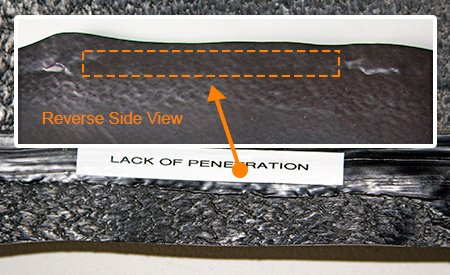

CAUSE: Too low of a pre-heat or not enough downward pressure by operator during welding (inexperience or carelessness).EFFECT: Low tensile strength at seam and seam separation under stress.

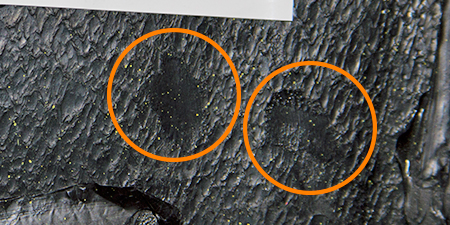

CAUSE: Too low of a pre-heat or not enough downward pressure by operator during welding (inexperience or carelessness).EFFECT: Low tensile strength at seam and seam separation under stress.Moisture Bubble

CAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat.EFFECT: Creates void in extrudate leading to holes.

CAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat.EFFECT: Creates void in extrudate leading to holes.Improper Tee

CAUSE:Inexperience or improper welding technique. EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.

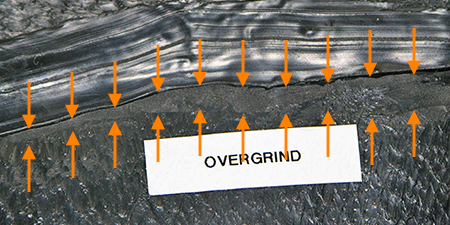

CAUSE:Inexperience or improper welding technique. EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.Overgrind

CAUSE: Grinding too wide, carelessness, or operator missing the joint during seaming.EFFECT: Thins the geomembrane and can remove UV protection such as for white liner. Can be a weak point.

CAUSE: Grinding too wide, carelessness, or operator missing the joint during seaming.EFFECT: Thins the geomembrane and can remove UV protection such as for white liner. Can be a weak point.Moisture Bubble

CAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat. EFFECT: Creates void in extrudate leading to holes.

CAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat. EFFECT: Creates void in extrudate leading to holes.Double Bead

CAUSE: Covering too wide a grind, inexperience, improper welding techniques.EFFECT: Multiple, concentrated heating events without cooling tend to cause burn-thru which leads to holes.

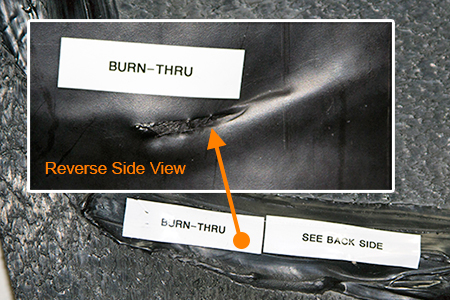

CAUSE: Covering too wide a grind, inexperience, improper welding techniques.EFFECT: Multiple, concentrated heating events without cooling tend to cause burn-thru which leads to holes.Burn-Thru

CAUSE: Excessive heating either from pre-heat setting or multiple passes with the extrusion gun, grind too deep.EFFECT: Holes = Leaks.

CAUSE: Excessive heating either from pre-heat setting or multiple passes with the extrusion gun, grind too deep.EFFECT: Holes = Leaks.